Like almost all modern kit cars the Haynes Roadster uses a double wishbone suspension. The front upright and rear bearings come from a Ford Sierra along with some other donor parts. The lower wishbones are made from 1" 16SWG seamless tube whereas the upper wishbones are ¾" 16SWG seamless tube. The reason for this is that the lower wishbones, during cornering, carry more load than the upper wishbones. Also the load experienced by the lower wishbone is compressive whereas the upper wishbone is tensile therefore the increased diameter of the lower wishbone not only gives it more cross-sectional area for the same wall thickness but also more resistance to buckling.

The Importance of adjustable suspension!

If you are building your own car be it for the road or the racing circuit it is extremely important that you build in some adjustment. Here are a couple of reasons why adjustable suspension is so important.

- It allows you to tune out any manufacturing errors. Imagine if you make the upper wishbones too long or too short and you cannot adjust the length then your camber angle is going to be wrong.

- It allows you to set the car up symmetrically. Using the

example of upper wishbone length again. Imagine if one upper wishbone is longer than the other. If you cannot adjust then to make them both the same then the car will handle differently when it is turning left vs when it is turning right.

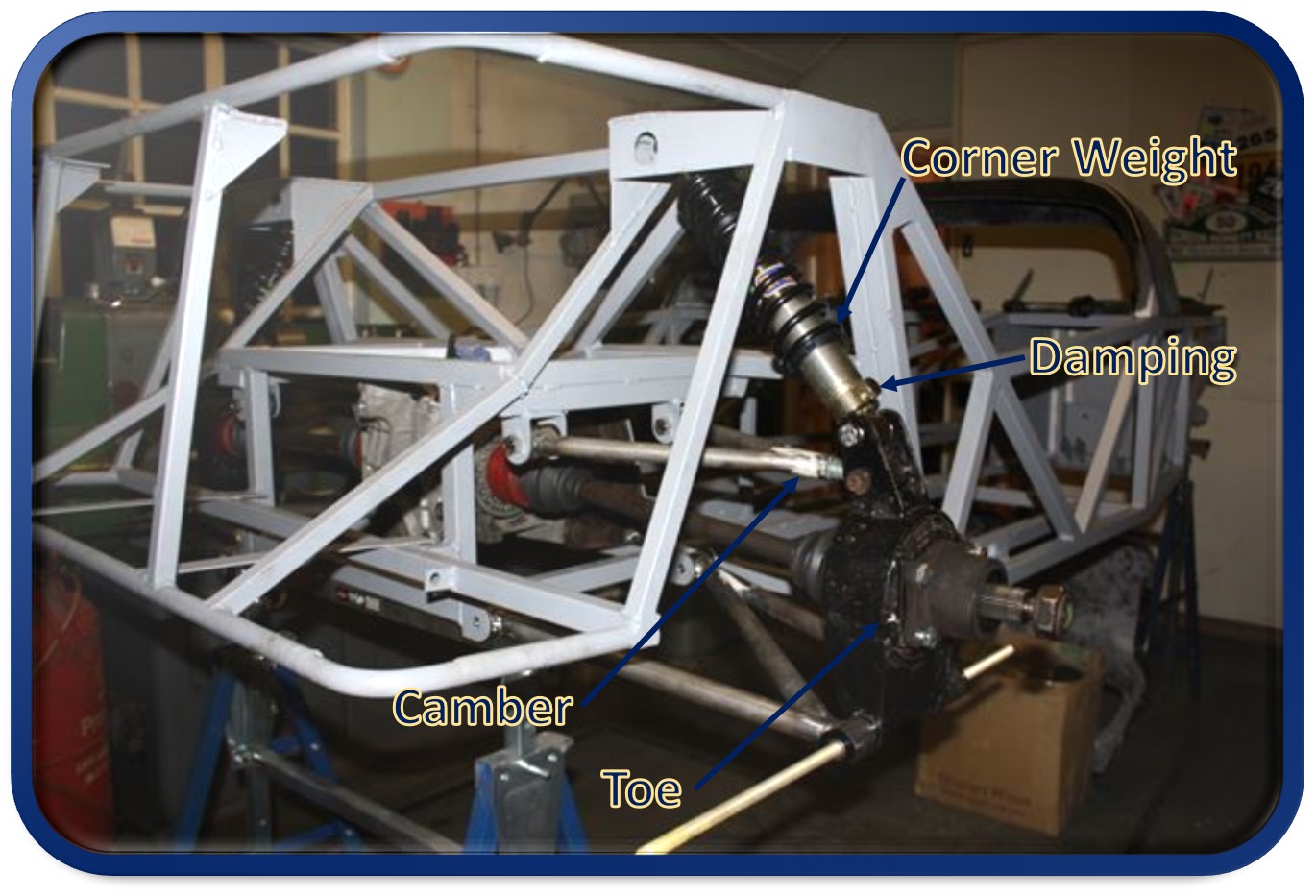

- It allows you to adjust the balance of the car. This is looking more at adjustable corner weight and damping. That said, toe, camber and other geometric factors do play a part in this but I think that might have to be an topic all on its own. Being able to adjust the damping of the front and rear axles allows you to easily adjust the cars ballance between oversteer, neutral steer and understeer. Being able to adjust the corner weights makes sure that each tyre on a given axle sees the same amount of load, this helps to ensure that the car feels the same regardless of whether it is turning left or right.

Looking at the rear suspension picture below you can see that there is Camber adjustment built into the upper wishbone in the form of a threaded joint. The toe angle can also be adjusted by placing shims between the rear upright and the bearing block and the corner weight and damping can be adjusted via the shock absorber.

Looking at the front suspension picture below you can see that there is Camber adjustment built into the upper wishbone in the form of a threaded joint. The toe angle can also be adjusted by turning the track rod extension. Corner weight and damping are adjusted in the same was as on the rear via the shock absorber. Unfortunately there is no way to adjust the caster angle with this design.