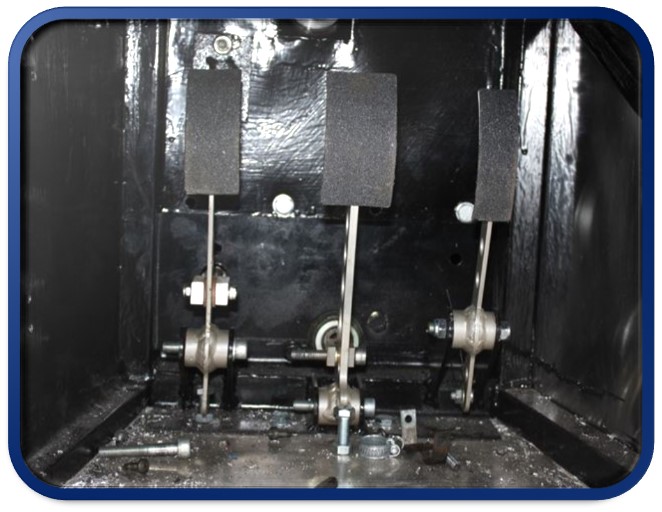

Welcome to part 4 of the Haynes Roadster build diary in this section we will be talking about the pedal box. The pedal box is a fairly simple assembly made from a couple of bent pieces and brackets made from 3mm mild steel plate. The whole assembly was MIG welded together. The clutch and accelerator pedals are also 3mm steel whereas the brake is 5mm since it is safety critical. The pedals pivot on Tufnol bushes that are secured with 8mm bolts.

Since I built the car using the Super Backbird engine the clutch is hydraulic rather than cable operated. It therefore seemed fairly obvious to use the bikes mater cylinder rather than having to go out and buy a different one, this did ultimately result in the clutch acting as more of a switch than the nice progressive clutch you get in a normal car. That said you only really need the clutch when pulling away and on the downshifts so it really isn’t a problem. The brake master cylinder is from a Ford Sierra but since the car is so light there is no need for the servo so that was removed. This does mean that the brake pedal feels quite heavy when you push it but the brakes are capable of locking the wheels so they are plenty powerful enough without it.

All 3 pedals can be slightly adjusted using turnbuckles to set the position relative to one another. The brake pedal also has an adjustable stop in the floor to aid with adjustment.

Making the pedal box was quite straight forward and proved to be a very satisfying part of the project. The main structure of the pedal box was primed in the same etching primer as the chassis then given a top coat of black Hammarite. I actually bought the pedals pre made, they are powder coated to protect them from rusting and have some skateboard grip tape on the petal faces to prevent my foot slipping off them.