Welcome to part five of the Haynes Roadster build diary, in this section we will be talking about the Haynes Roadster engine. When I first built the car I really wanted a Honda S2000 engine, but I couldn't afford one. So, I settled for what I considered to be the next best thing, a Honda super Blackbird motorcycle engine. The super Blackbird engine produces approximately 170 hp and comes with an integrated six speed sequential gearbox. That makes for a lot of fun in such a light weight car. I managed to pick up a 2001 engine with about 20,000 miles on the clock for just over £1000.

I had read online that the Honda Blackbird engine was susceptible to oil starvation when mounted in a car. As a motorcycle corners the bike leans and the oil stays parallel to the bottom of the sump. Since a car does not lean when cornering the oil in the sump 'surges ' to the side. This leads to the oil pickup being uncovered and ultimately starves the engine of oil. There are a couple of ways to combat this including; a baffle plate, an Accusump and the most expensive option, a dry sump. I opted for a baffle plate as I could not afford the other two options.

Installing the Haynes Roadster engine

Installing the engine is a relatively simple affair. It involved making a removable frame from 1" box section to support the engine within the chassis. I connected the frame to the engine using existing pickup points on the cylinder block. The chassis needed some additional brackets welding on to be able to support the engine frame. The brackets were made from 3mm mild steel and secured the frame with M12 bolts.

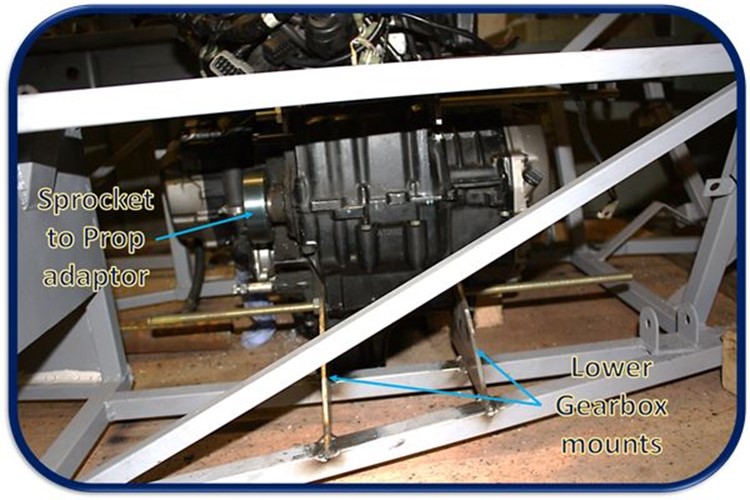

I also added some 5 mm thick tabs to the chassis as gearbox mounts. Since the car would be loud and antisocial anyway; I decided to rigidly mount the engine rather than using rubber bushings. Comfort is overrated anyway.

Since the car uses a Propshaft rather than a chain drive, the sprocket was removed and replaced with an adaptor. The adaptor fits on the gearbox output shaft splines and provides a flange for the Propshaft to bolt up to.

Gear linkage

Since the motorcycle engine uses a sequential gearbox the gear linkage is quite straightforward. On a motorbike you normally change gear using your foot; in a car by using your hand. I therefore had to come up with a system to convert from foot to hand operation. To do this I used the existing foot operated gear lever and connected it to a simple push pull lever in the cockpit via a Bowden cable.

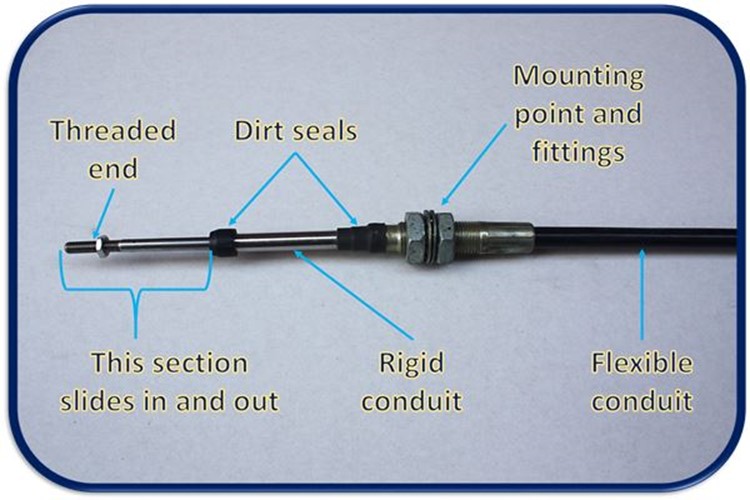

If you are not familiar with Bowden cables they are essentially a steel cable with threaded ends inside a flexible plastic conduit. Due to its design the Bowden cable can transmit push and pull forces around corners making it ideal for a gear linkage.